CP4WT (Coated Pins for Wind Turbines)

- ist-aachen

- Aug 4, 2025

- 2 min read

To achieve national and international climate goals, the expansion of wind turbines (WT) plays a central role. To meet these goals, wind turbines must deliver increasingly higher performance while reducing costs at the same time. This requires gearboxes with higher torque density and lower costs. To meet these requirements, plain bearings are used in the planetary transmission. Conventional plain bearing concepts, consisting of a steel pin fitted with a bronze bushing, present economic challenges in terms of manufacturing and material costs. To address this, modern bearings apply a thin bronze coating directly onto the pin. Common manufacturing processes for this include Laser Cladding (LC) or Extreme High-Speed Laser Cladding (EHLC).

Plain bearings are often tested on radial load test rigs, which, however, cannot apply realistic load collectives. The additional moments generated in wind turbine (WT) gearboxes by the helical gears of the planetary stage cannot be adequately replicated. This results in abstraction losses that make it difficult to transfer test rig results to real-world applications. To account for these real loads, subsystem test rigs must be used, which involve high effort and operating costs. Thus, cost-effective testing and precise evaluation under real load conditions is not possible. For the design-qualification of plain bearing concepts with coated pins, a novel test rig is therefore needed that allows testing of the bearings under real load conditions.

Research Objectives

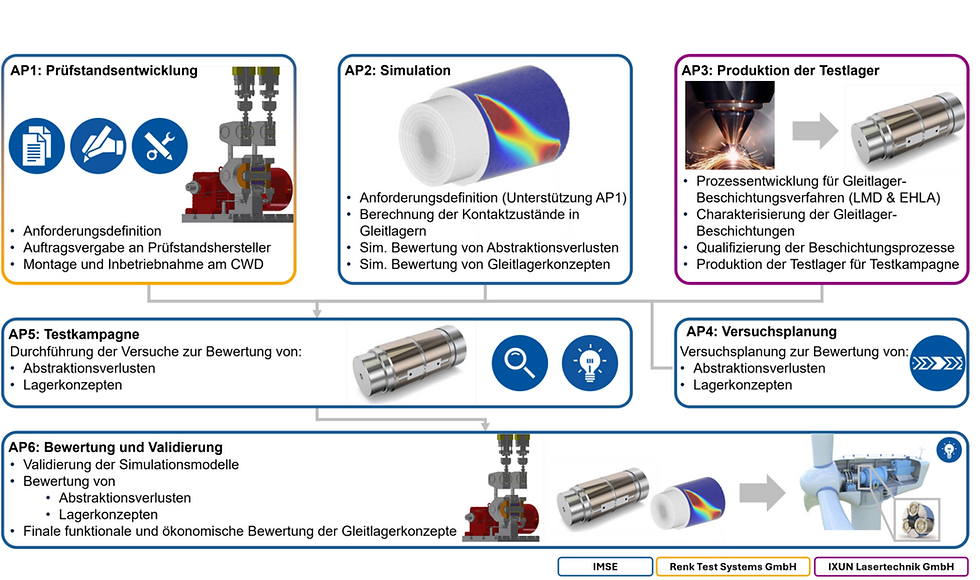

The main goal of CP4WT is the functional and economic analysis of coated planetary pins in wind turbines with respect to manufacturing processes and process parameters. To test the bearing concepts cost-effectively under real load conditions, a novel test rig will be developed and built.

The sub-goals of the project are:

Identification of critical load conditions in planetary gear plain bearings of WTs

Development and validation of a suitable test rig using CAD as well as FEM and EHD software

Simulation-based evaluation of abstraction losses and the plain bearing concept

Characterization of plain bearing coatings and qualification of the coating processes

Planning and execution of a test campaign to qualify the bearing concepts and abstraction losses

Project Duration

01.04.2025 - 31.03.2028

Project Partners:

Renk Group AG, Ixun Lasertechnik GmbH, Schaeffler Technologies AG & Co. KG, Kuglerbimetal, SKF Group, Flender, Acunity

Funded by:

European Regional Development Fund (ERDF)

Lead Partner:

Projektträger Jülich (PTJ)